Machine Data Monitoring (MDE)

Partner: GNT Systems GmbH

Segment: Software Systems

Process: MES

Segment: Industry 4.0, Process monitoring

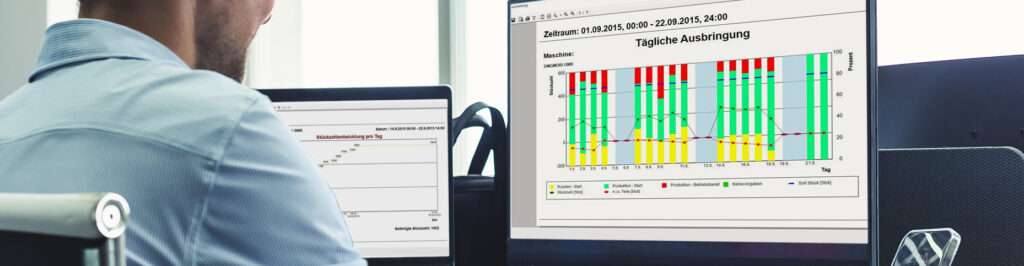

Machine data acquisition involves gathering information from various types of systems such as machines equipped with CNC or PLC controls, automated production stations, and more. This acquisition can be done through different methods like connecting via external hardware modules to record digital and analog states, or directly through software interfaces like OPC UA, EUROMAP, MT-CONNECT, UMATI, and other similar protocols. This process enables the collection of valuable data that can be used for monitoring, analysis, and optimization of machine performance and production processes.

Production Data Monitoring (BDE)

Partner: GNT Systems GmbH

Segment: Software Systems

Process: MES

Segment: Industry 4.0, Process monitoring

The BDE terminals situated on-site play a crucial role in enhancing the accuracy of data collection. These terminals allow for the straightforward input of disruption triggers and causes within the production setting. Additionally, they facilitate the display of essential production data, including documents and drawings. Moreover, these terminals enable direct feedback integration into the ERP system, streamlining operational processes effectively.

Visio Planning System

Partner: GNT Systems GmbH

Segment: Software Systems

Process: MES

Segment: Industry 4.0, Planning System

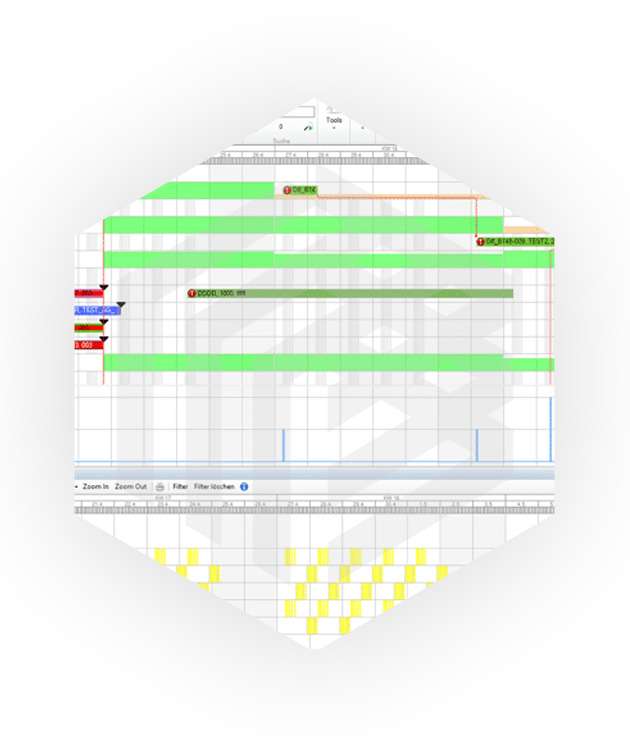

Automatic detailed planning based on the available resource entails creating a meticulous plan without disrupting current operations. This involves deploying personnel according to their qualifications to ensure efficient execution of tasks. By directly linking to the MDE / BDE system, backlogs and delays can be easily identified and displayed in real-time, enabling proactive measures to be taken to address any issues promptly.